Ever wondered how changes in the macroeconomic scenarios are making corporations turn their attention to the finer aspects of execution? This is being done by inspecting the levers that change the microeconomic landscape.

Existing levers such as Cost, Quality and Time (triple constraints) are now more of a hygiene factor and not a WOW factor or differentiator. This added to the fact that humans, as rational beings often find delivering repetitive tasks a source of boredom that takes away the focus from core activities.

We are aware that robots have been in existence in physical form for some time now for doing things that are out of bounds or considered risky for humans. For instance, robots are deployed in military services, car production, investigating hazardous environments and space exploration, to name a few.

There is also a considerable gap in the industry between the workforce needed and the glut of human capital available. All of which has led to the need for Robotic Process Automation (RPA).

What is RPA?

Robotic Process Automation (RPA) involves software robotic processes instructed to do repetitive tasks day in and day out. The only difference is that, for now, they do not think/adapt themselves.

However, with the inclusion of artificial intelligence and machine learning, this may change. The other point to note is that the robots are software robots and hence managed through software. There is another advantage to the RPA proposition; the robots run in dual mode: with or without human intervention.

Why Robotic Process Automation (RPA)?

RPA technology offers some inherent benefits.

- 1) Non-invasive: you do not need to change your existing IT infrastructure and incur huge operational costs.

- 2) Faster ROI: they learn and implement fast.

- 3) Error-free: robots are less prone to making mistakes while performing repetitive tasks for a long period. They offer accuracy for regulatory and compliance tasks such as in the Global Data Protection Regulation (GDPR).

- 4) Round-the-clock management: The technology operates 24x7x365 other than for planned maintenance and upgrades

- 5) Co-exists: with human capital, aiding the human workforce to concentrate on value-added creative tasks and have a better work-life balance

- 6) Scalable: provides on-demand team flexibility for agility, scalability and sustainability

- 7) Process improvements: feasibility studies undertaken during the RPA implementation phase not only identify the process for RPA implementation but also help identify process improvements for those processes that do not fall under the realms of RPA implementation.

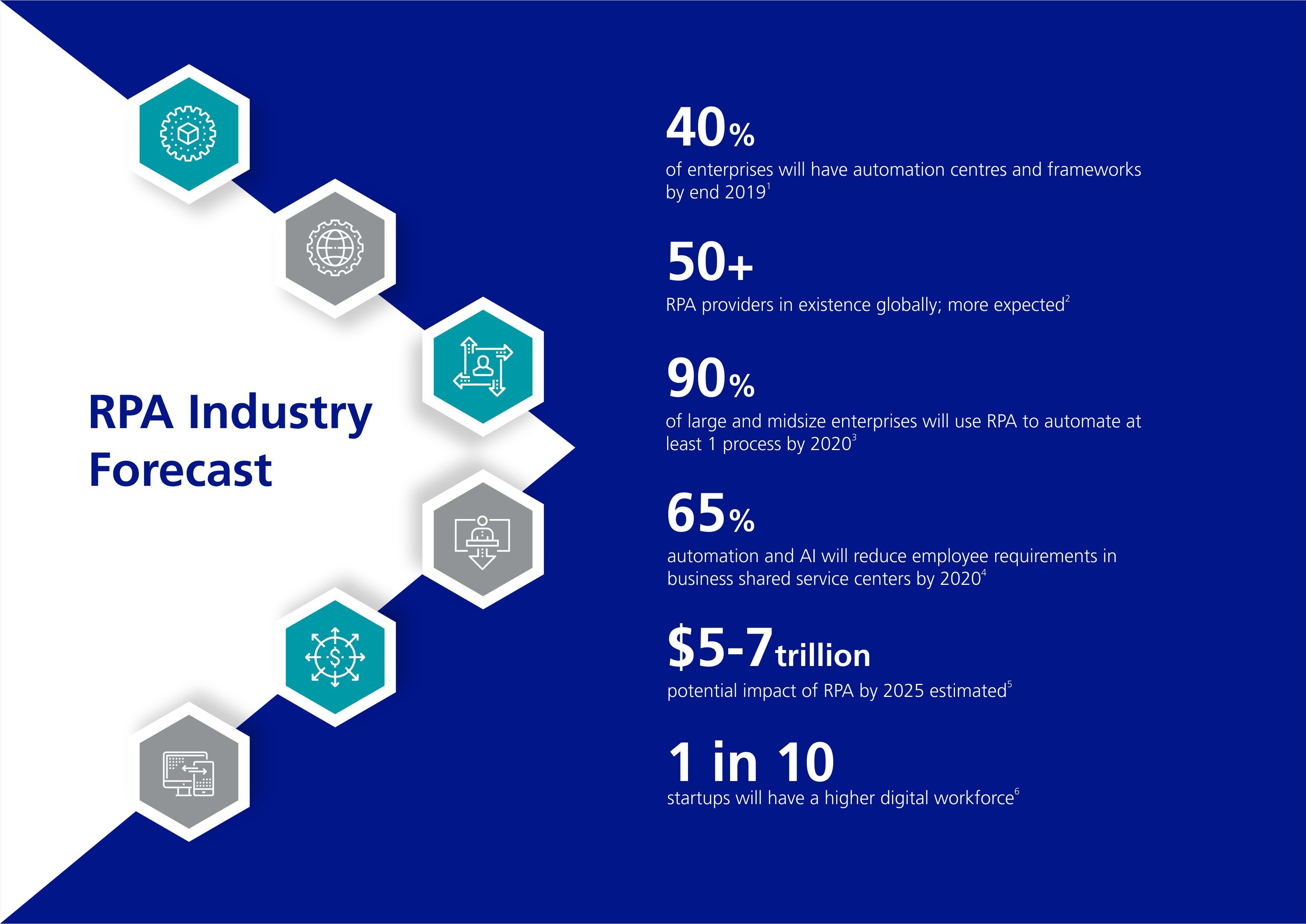

The diagram below details some RPA statistics and forecasts.

Source:1 and 5: Forrester; 2 and 3: Gartner; 4: CIO; 6: UI Path

Where can we implement RPA?

Robotic Process Automation (RPA) can be implemented across a range of industries and processes. However, it is best suited for processes that:

- i) Are highly manual and repetitive

- ii) Are rule-based and have few or few exceptions to the rule

- iii) Involve high-volume transactions

- iv) Include mature and stable processes

- v) Are non-intrusive implementations (no changes to the existing hardware or software)

- vi) Include a high degree of human involvement (to execute the process) and

- vii) Offer maximum Return on Investment (ROI)

While the above list is not extensive, it provides a view of processes that need to be automated using RPA. Identifying the candidates for automation is the first and the most important part of any Enterprise Automation Journey.

Enterprises should carry out this study across the breadth and depth of the organisation, to maximise the benefits of RPA automation. This is because the study will help define an automation roadmap for achieving maximum benefit.

Want to succeed with your RPA implementation? Connect with us to find out how we can help.