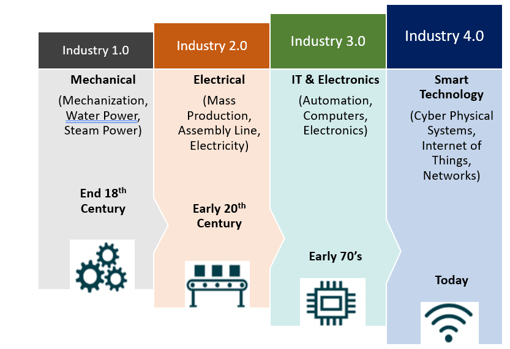

Industrial Revolution: Industry 4.0

When we look at the industrial revolution that the manufacturers have been through, it all started with the Invention of new machines, improvements in logistics and communication, and new energy resources.

Then came the second revolution wherein revolution was majorly around the setup of production lines, mass production and most importantly use of electricity.

Automation software also made its debut at this time, taking over many of the tasks previously completed by humans.

Industry 4.0 originated in 2011, largely promoting the computerization of manufacturing.

A type of the Fourth Industrial Revolution, Industry 4.0 involves the continuous automation of manufacturing and industry practices by means of smart technology where everything “talks” to each other.

Industry 4.0 focuses on the Internet of Things and is driven by smart technological developments needed to establish an interconnected digital manufacturing enterprise, which also communicates, analyzes, and uses data to drive further intelligent action back in the physical world.

The Future Trends in the Manufacturing Industry

The manufacturing industry was hit hard during the pandemic, but it has managed to bounce back stronger; a recent report states that industrial production and capacity utilization in the US markets stood higher at present compared to the pre-pandemic levels.

To keep up with the changes, manufacturers are now focusing on adopting smart factory solutions to drive growth and innovation.

Let’s explore some smart manufacturing trends in detail.

1. Adopt a cloud-first approach

Cloud offers customization, flexibility, agility, scalability, and cost advantages, along with providing industry-specific offerings. With Oracle manufacturing, manufacturers can gain an advantage from a performance, security, and flexibility perspective. It gives manufacturers easy and low-cost access to new smart technologies and provides opportunities to offer new services to their customers.

2. Transform existing supply chain operations

For effective operations, supply chain management requires end-to-end visibility of raw materials and finished goods at all production and delivery stages. Leveraging Oracle SCM Cloud solutions will enable production managers to meet demands by managing assets and inventory efficiently.

3. Leverage AI solutions in manufacturing

Manufacturers can use AI solutions to detect failure patterns in machinery and components; for example, when a machine or part of it is likely to fail, manufacturers can take preventative action to maintain their equipment effectively.

4. Incorporate Collaborative robots in manufacturing

Robotics in manufacturing is one of the key automation enablers that manufacturers can leverage to achieve greater efficiencies; e.g., robotic exoskeletons can assist production line workers to lift heavier parts without compromising safety.

5. Achieve predictive maintenance

Predictive maintenance monitors the condition and performance of connected machines & assets, improving asset availability and performance. For example, sensors on factory equipment enable transmitting critical data regarding equipment health and utilization.

With this feedback, manufacturers can maximize equipment uptime and avoid operational disruptions. Manufacturers can use sensors to analyze data on older motors and transmissions for interpreting a machine’s condition and detecting irregularities.

Taking a Step Toward Smart Manufacturing

Smart manufacturing is a multi-faced approach involving the following notions:

- Integrate: Connect, collect, and communicate

- Discover: Clean unknown insights

- Decide: Make intelligent judgments

- Execute: Execute proactive & predictive actions

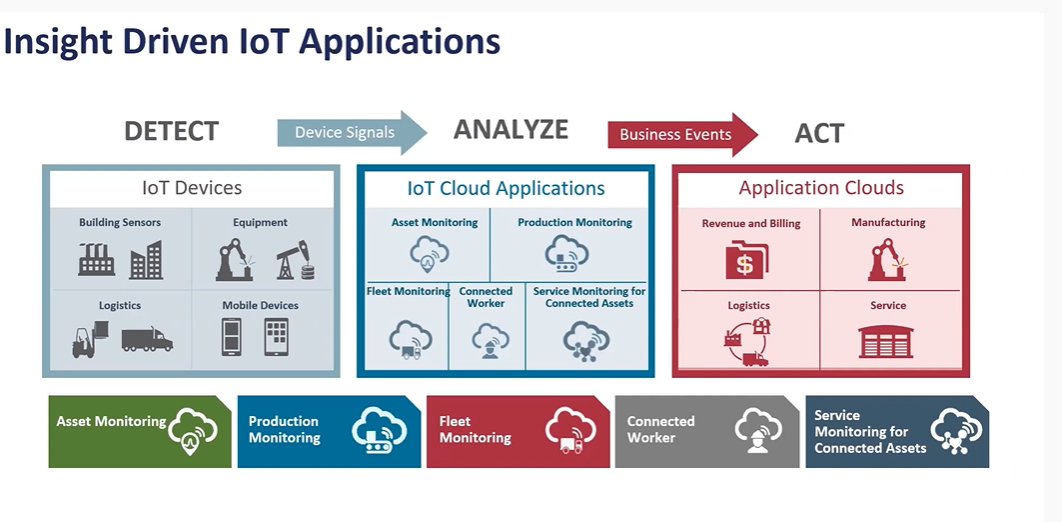

Adding to it, insight-driven IoT (Internet of Things) applications are an integral part of the smart factory industry 4.0, allowing companies to act quickly in detecting and analyzing problems. McKinsey reports that IoT will be a $500 billion market by 2025 as advances in its essential technologies drive up demand.

You can use artificial intelligence-based forecasts for new product launches. Predictive maintenance can be used to predict what assets and machines require maintenance, so you can efficiently plan and schedule parts inventory. IoT applications assist in identifying the work orders that are at risk for manufacturing use and the ETA for fleets.

Oracle Supply Chain Cloud for Smart Manufacturing

Oracle offers a comprehensive set of planning and execution applications for manufacturers to perform different processes:

1. Ideate to Commercialize directly supports organizations in achieving a quicker product launch as well as efficiently managing the product life cycles.

2. Source to Settle solutions solves the day-to-day needs of the procurement department like collaborations on video platforms, punching out catalogs, etc.

3. Order to Cash solutions drive sales processes, aid in achieving on-time delivery for customers, and configure order needs for manufacturers.

4. Plan to Produce solutions offer manufacturers end-to-end integrated processes ranging from demand forecasting, MRP, manufacturing, and quality management.

5. Maintain to Optimize cycle assists organizations look after the maintenance-related aspects of equipment and other assets.

6. Logistic solutions cater to the needs of warehouse management, fleet management, transportation planning, and optimization.

Our Accelerators to Enable Smart Manufacturing

With 15+ years of experience in implementing Oracle solutions, we have designed and developed industry-focused accelerators for manufacturers to achieve business transformation without compromising on their daily operations.

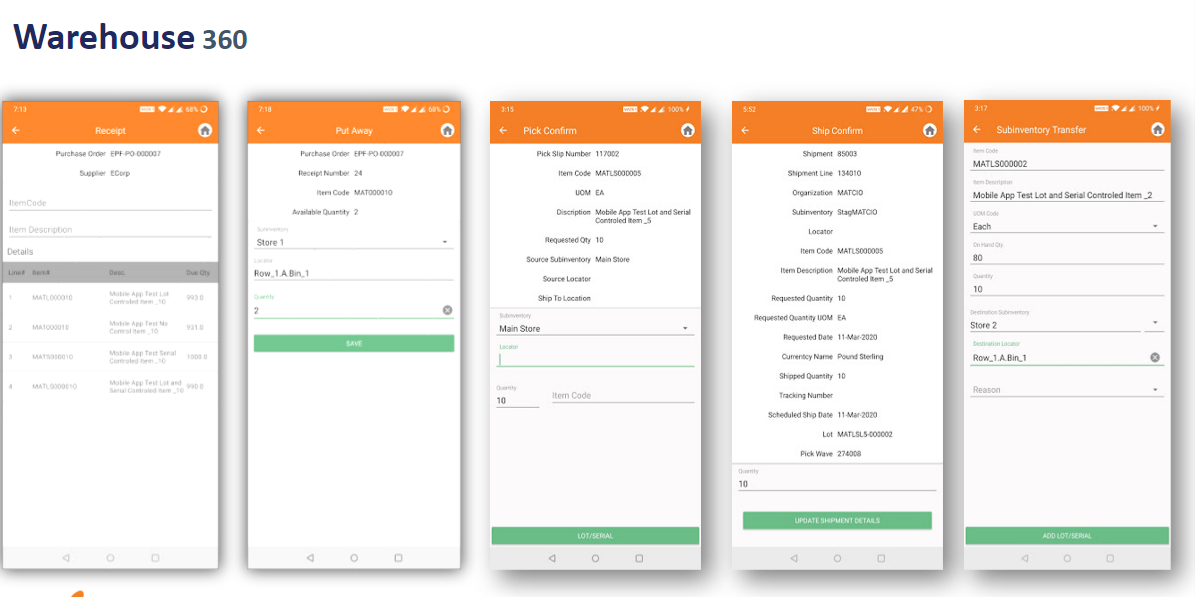

1. Warehouse 360 is a best-of-breed mobility system, which works in conjunction with Oracle SCM Cloud to provide greater visibility of warehouse and shop-floor transactions. It helps you prepare for different real-time situations like changes in orders, emergency shipments, stock movements within the warehouse, decreases, and increases in inventory.

2. Our Value-Based Analytics™ tool is developed with the focus to measure and monitor the ROI for which the system/transformation was implemented. It is an efficient way to realize measurable business value with Oracle Cloud, so companies get insights into process optimization and system adoption.

We Are Here to Help You!

One of our customers, Zamil Industrial Investment Company (ZIIC), wanted to achieve process improvements and adoption of Industry 4.0 Best Practices mainly around Manufacturing & Planning business areas, Engineer to Order Process and Product lifecycle management. The success at Zamil also had improvements in integrated logistics planning, optimized loading, and saved time through solutions of Transportation Planning.

If manufacturers want to optimize procedures using the latest technologies, adopting smart manufacturing solutions is the key to implementing continuous operational improvement and having real-time awareness of the state of production equipment and raw materials.

If you would like to explore smart factory solutions and are looking for an Oracle Cloud partner to join hands with, contact us today.